DTU unveils 3D-printed gyroidal solid oxide cells in fuel cell technology for compact hydrogen conversion

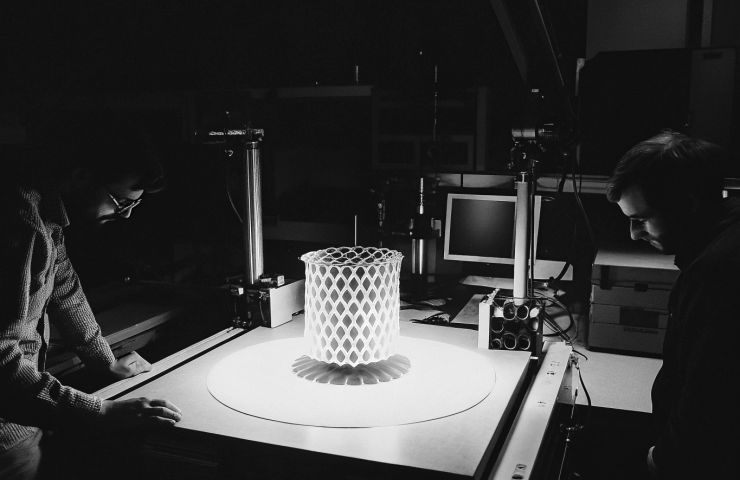

August 20, 2025In August 2025, a team at Technical University of Denmark (DTU) led by Prof. Vincenzo Esposito, Dr. Zhipeng Zhou and Dr. Venkata Nadimpalli rolled out a one-of-a-kind 3D-printed monolithic gyroidal solid oxide cell (3D-SOC). Designed just outside Copenhagen, this clever device can switch between a fuel cell and an electrolyzer without any bulky metal interconnects, making it lighter, more compact, and potentially tougher than the usual layered SOC setups. By merging functions into a single ceramic piece, they’re shaking up fuel cell technology and opening doors for future hydrogen fuel cells and electrolysis systems.

- The gyroid geometry creates a massive surface area and even gas flow inside one seamless ceramic lattice.

- Swapping out metal interconnects for an all-ceramic build cuts both weight and corrosion headaches.

- It smoothly toggles between SOFC mode (fuel cell) and SOEC mode (electrolyzer).

- Potential use cases span aerospace, automotive fuel cells and stationary power, thanks to simpler production.

- We’re still waiting on third-party data for exact performance stats—think efficiency and power density.

Solid oxide cells aren’t new. For years, they’ve been stacked in flat layers held together by metal plates. Those metal bits conduct electricity fine but add weight and can corrode over time—especially in harsh environments. Fast forward five years, and additive manufacturing has come a long way, letting engineers whip up intricate 3D shapes. Meanwhile, gyroid patterns—once mainly for heat exchangers—have proven they’re top-notch at managing fluid flow and structural strength. DTU’s 3D-SOC is one of the first to plug that gyroid magic into real-world sustainable energy gear.

It all starts with a digital gyroid model that gets sliced into ultra-thin layers. A specialized ceramic 3D printer then lays down a slurry, curing each layer on the spot to keep those tiny channels intact. Once printing wraps up, the whole piece goes through co-sintering, bonding electrolyte and electrodes into a single, porous ceramic marvel. After that, the gyroid surfaces get a coat of electrode inks, creating seamless ion and electron highways. No more gaskets, no more sealants—just one piece doing it all, which slashes assembly and cuts internal resistance.

Lab tests show the gyroid shape keeps gas flow steady and spreads heat evenly, dodging hotspots that could wreck performance. They’ve nailed dual-mode operation in the lab, but the big questions—long-term durability and real-world efficiency at scale—are still on the table. As Nature Energy noted, this could be a game-changer for scaling up, but we’re waiting on independent verification to see if it really delivers.

Business & Strategic Angle

By streamlining the supply chain and slashing production steps, DTU’s 3D-SOC could seriously drive down manufacturing costs. Printing an entire fuel cell stack in one go means fewer parts to source, inspect, and assemble. Industry heavyweights like Airbus and NASA are already circling this tech for weight-sensitive projects, though they’re still in the “potential adopter” camp, not formal partners. In the automotive world, lighter stacks could speed up the rollout of hydrogen fuel cells in commercial fleets, giving a boost to green hydrogen as a clean transport solution.

On the policy side, simpler designs might snag funding under clean energy and industrial decarbonization schemes. Areas with beefy 3D printing scenes—think Scania in Sweden and the U.K.’s Manufacturing Technology Centre—could be perfect launchpads for pilot runs. Stakeholders will be crunching the cost-per-kilowatt-hour numbers against durability and complexity to see if DTU’s approach really hits the sweet spot.

Collateral Impacts

If 3D-printed SOCs go mainstream, we’ll likely see new supply chains spring up for high-purity ceramic powders and advanced electrode materials, giving chemical suppliers a lift. Ditching metal interconnects also shrinks the carbon footprint of cell production, which is a big win in life-cycle analyses for green hydrogen projects. Fewer seals and metal parts mean lower failure rates and easier maintenance—good news for anyone running power plants or off-grid stations. Modular, monolithic units promise faster installation and quicker swaps when things need servicing.

When working as an electrolyzer (SOEC), these 3D-SOCs could make green hydrogen output more efficient by keeping gas flow consistent and cutting energy use per kilo of H₂. And since there are no metal cell joints to fail, uptime should get a boost. Paired with renewable electricity, they fit right into broader hydrogen infrastructure plans, offering scalable, modular electrolysis options for grid balancing and storage.

Even university labs and small R&D outfits could cash in. No fancy press-joining rigs needed means lower startup costs for prototype SOCs, which could spark more rapid innovation cycles. That feedback loop might drive costs down further and broaden use cases beyond transport—imagine remote telecom backups or island microgrids powered by these neat little ceramics.

Closing Insight

Sure, DTU’s 3D-printed gyroidal SOC is still in its early days, but it’s a clear sign of where fuel cell technology is heading: complex systems distilled into single-piece ceramics. If the promised gains in efficiency and durability play out at scale, we could be staring at a whole new era for hydrogen fuel cells and electrolysis. For anyone tracking sustainable energy and industrial decarbonization, this is one to watch—you might just see the next big leap in clean power tech unfold here.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.