Can the Rotary Engine Help Take Hydrogen Mainstream as a Transportation Fuel?

November 12, 2024Hydrogen as a “clean” energy source attracts billions of dollars in public and private funding every year. The U.S. government has created multiple programs to stimulate production and use, resulting in steady growth in interest and investment. And the U.S. and other countries clearly have the technology and natural resources to produce a lot of hydrogen.

On top of that, hydrogen has long been used in multiple industrial sectors, such as oil refining, methanol production, and ammonia production – and those traditional chemical processing applications continue to grow steadily.

But – for hydrogen to become truly mainstream – it will have to play a big role in transportation, and even with all of the investment currently taking place, today that future seems far off.

Hydrogen’s Potential and Challenges as a Transportation Fuel

Hydrogen commands attention as a potentially-attractive transportation fuel because of two key attributes:

- It’s more energy-dense than fossil fuels, which themselves are already up to 100 times more energy-dense than the best batteries on the market.

- It’s clean-burning, with few emissions or byproducts beyond water. If produced cleanly (i.e., using renewable electric energy to hydrolyze water or from natural gas with effective carbon capture), hydrogen can have a very low carbon footprint.

But the current drawbacks are significant. Hydrogen is a very reactive and small molecule, and it needs specialized equipment for safe transport and storage to prevent boil-off fuel losses, dangerous leakages, and material embrittlement.

There are other drawbacks beyond the production and storage. The piston engine–the ubiquitous cost-effective device to convert fuel energy into mechanical work–is not well suited to burning hydrogen. Hot spots increase the risk of pre-ignition and engine knocking, and faster flame speed can cause reliability problems. In gaseous form, hydrogen has low volumetric density, meaning that a lot of air is displaced, leaving less available oxygen and reducing overall power density and potentially reducing efficiency.

Given those challenges, a “transportation-mainstream hydrogen” is unlikely to involve existing car piston engine designs. That has auto manufacturers experimenting with and promoting Fuel Cell Electric Vehicles (FCEVs), which use on-vehicle hydrogen fuel cells to power electric propulsion motors, like what you may see in Hyvia’s vans or the Toyota Mirai.

However, hydrogen fuel cells themselves have many limitations. Of note, the U.S. Department of Energy says they are not as durable as internal combustion engines, with durability at 50 percent of what is needed for commercial adoption.

Why the Rotary Engine Is Hydrogen’s Mobility Future

As noted above, the need for a safe, inexpensive, and reliable way to turn hydrogen into propulsion is critical. Piston engines cannot readily do it, and fuel cells are expensive and unreliable. So, are there other hydrogen conversion-to-power conversion innovations that could be mass-produced for transportation and other mainstream distributed and mobile applications?

The answer is yes. More specifically, the answer is the rotary engine. Rotary engines are superior to piston engines in burning highly reactive fuels like hydrogen, and manufacturers and hydrogen proponents should support innovations in this area.

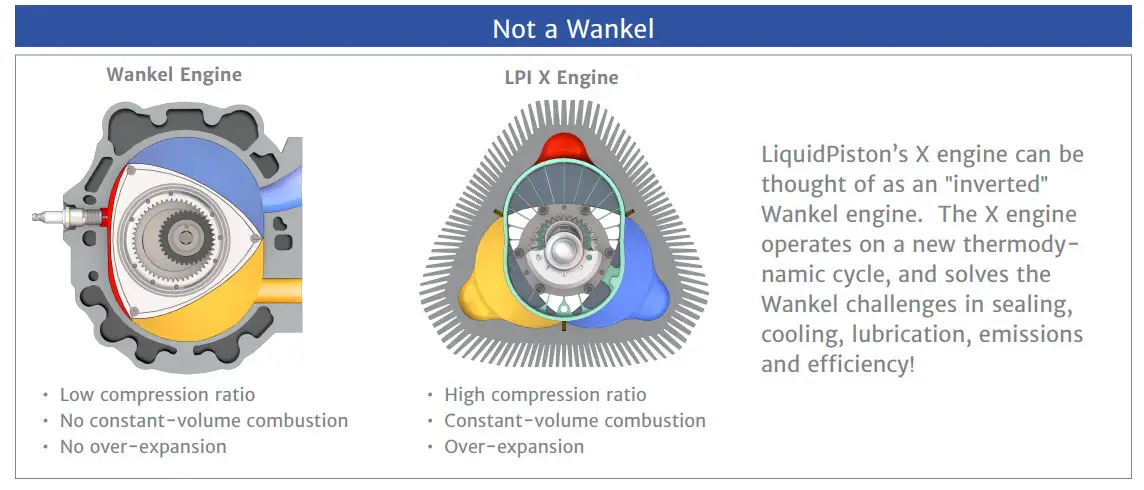

My company’s flagship rotary engine, the X-Engine, has successfully burned gaseous hydrogen to power a hybrid-electric go-kart (in fact, with its “inverted Wankel” design, the engine can burn pretty much anything effectively, even vodka). Our development roadmap includes engine balance of plant components and sub-systems optimized for storing, injecting, and handling hydrogen.

In short, a hydrogen-powered mobility future is technically very feasible with current internal combustion engine innovation, specifically in rotary engines. Assuming that the distribution and storage infrastructure challenges are overcome in order to support the hydrogen market at large, perhaps one day in the not too distant future, we will see many hydrogen powered vehicles, from the family hauler to selected aircraft.

Per Suneby is a director and senior vice president of corporate development for LiquidPiston, a leading developer of combustion engines and hybrid power solutions that are scalable, compact, and capable of utilizing efficient fossil or renewable fuel.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

Check out Samuel Baylin’s rotary engine patent from the 1920’s, which was long before the Wankel engine, and likely where Wankel got his idea. It was a pure rotary engine, unlike Wankel’s, according to the inventor, whom I knew. It’s about time Samuel Baylin got credit for being the father of all this approach, in my humble opinion.