2.5MW Containerized Hydrogen Electrolyzer contributes to the popularization of “Green Hydrogen”

October 27, 2021“Green hydrogen”, which utilizes renewable energy and electrolyzer to produce hydrogen, eliminates carbon emissions from the source and makes hydrogen the truly clean energy.

It is becoming the focus of the industry as an emerging field to achieve climate goals. “Green hydrogen” has several advantages over traditional hydrogen production methods:

- The raw materials are “green”, whether it is water or other renewable energy used to generate electricity, are environmentally friendly, and the electrolysis of water to produce hydrogen will only generate hydrogen and oxygen, not greenhouse emission to cause environmental pollution;

- “Green hydrogen” can solve the problem of redundancy and intermittent renewable

- The feedstock water used for hydrogen production is one of the most readily available resources in real life, so there is no need to consider the amount of feedstock. People in the industry generally believe that hydrogen as an important industrial feedstock and clean fuel will form a competitive pattern of the coming decades. and we have already seen the demand for green hydrogen is rapidly growing

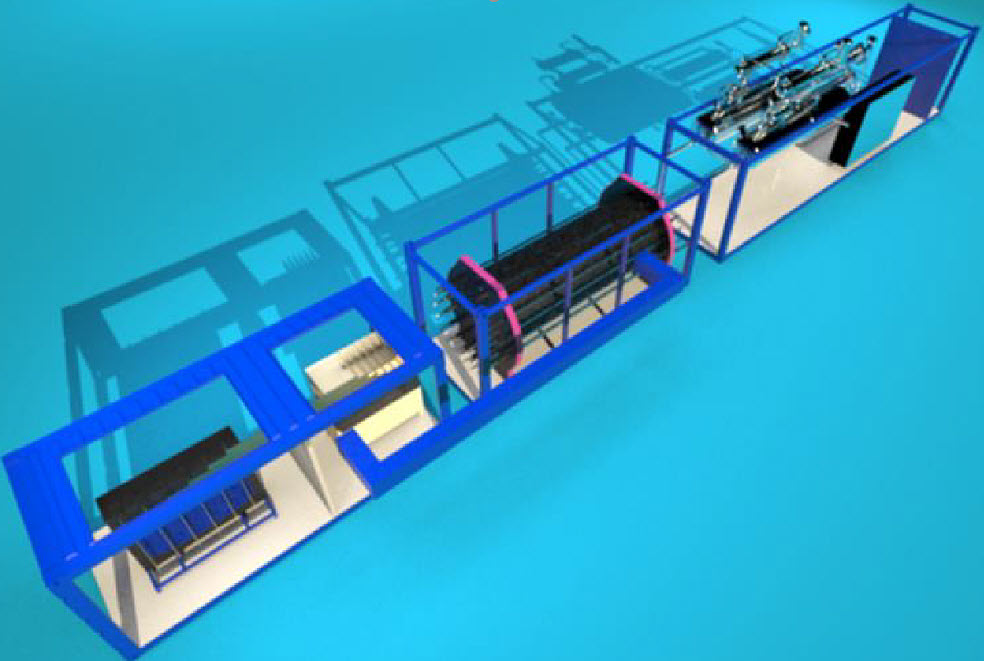

At present, the emergence of Angstrom’s 2.5MW Containerized single-stack Hydrogen Production System has contributed to the popularization of “green hydrogen”. This system adopts advanced water electrolysis hydrogen production patented technology, the total footprint only occupies 2 of 40ft containers (1 40ft and 2 20ft). and the system can be modularized to 10MW/100MW or larger module scales.

| 2.5MW Containerized Hydrogen Production System Specifications | |

| Type | Alkaline Electrolyzer |

| Model | VERDE-500-1.6 |

| Hydrogen Capacity Nm3/h | 500 |

| Oxygen Capacity Nm3/h | 250 |

| Purity % | 99.7 (99.999% after purification) |

| DI Water Consumption L/h | 500 |

| Max Output Pressure MPa | 1.6 |

| Power Range | 0-120% |

| DC Power Consumption | 3.9-4.5 kWh/1 Nm3

*~20% less than traditional H2 Plant |

| Commission Time for the System | 2 -3 weeks

* 80% less than traditional H2 Plant |

| Environment | -40-60DegC, outdoor installation

* only indoor installation for traditional H2 Plant (5-35DegC) |

The successful development and production of the system is the result of the combination of the US leading both the technological progress and industrial development trend; it is also a breakthrough in promoting the development of the global hydrogen energy industry.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

Hi,

We are interested in off-grid power Mini-grids for Drip irrigation Grids for small farms in Benin, West Africa. We have one well 400 Feet deep that is Solar powered that also powers Palm oil Extraction Machines.

Small farms produce 90% of the food in Benin on just over 1 million hectares of land and approximately 500,000 small farms. The world Bank funded a Solar-powered Drip Irrigation Project in northern Benin that was highly successful. However, we had to add a bank of Batteries to cover start-up power demands and anything more than 6 hours per day for Solar Power for our Demonstration Farm. We also have post-harvest preservation of Food. Benin Farmers annually lose 30% of their crops post-harvest. There is a huge demand for Off-grid Power. The Millenium Challenge Corporation state that the provision of power and Agrotechlolgy has the greatest impact on the economic development of developing nations.

MEDIC has had 100% repayment of loans to Benin Co-op Farmers.

Shall we talk?

Dr.Robin Knudsen VP MEDIC

(Mercy Economic Development International Corp).

[email protected]