H2 WOW Factor of Hazer Group Clean Hydrogen and Graphite Production

February 4, 2024As the world grapples with the unfolding climate crisis, the quest for sustainable and environmentally friendly energy solutions takes center stage. Leading the charge in this green revolution is Hazer Group, an innovative company poised to redefine the dynamics of hydrogen production. The patented Hazer Process, a pioneering technology developed by Hazer Group, marks a significant departure from conventional methods by transforming natural gas into hydrogen and graphite, with the ingenious use of iron ore as a catalyst.

The company has recently reached a significant milestone with the successful startup of its Commercial Demonstration Plant (CDP). The CDP has begun production of low-cost, low-emission hydrogen and graphitic carbon, marking a pivotal moment for the company. As Hazer plans to increase operations throughout the first half of 2024, it aims to demonstrate continuous operation at a commercial scale. This will significantly strengthen their global commercial project portfolio and further validate their groundbreaking technology.

Innovative Hydrogen Production

Hazer Group: Catalyzing Change in the Clean Hydrogen Market

In the dynamic sphere of the renewable energy market, few advancements have sparked excitement quite like the innovations erupting from Hazer Group. This forward-thinking company is revolutionizing the hydrogen industry with a proprietary process that stands to eclipse traditional methods. At the heart of this technological leap is the Hazer Process – a unique approach to producing hydrogen that also sequesters carbon in the form of high-quality graphite. It sidesteps the conventional reliance on fossil fuels, instead utilizing biogas derived from biomass and waste, thus promising a significant reduction in carbon emissions.

Hazer Group’s innovative process has the potential to be a highly cost-effective solution in the global graphite and hydrogen markets, thanks to its use of inexpensive feedstocks and catalysts. The production of both hydrogen and high-grade synthetic graphite concurrently further enhances the cost competitiveness of their approach. This isn’t merely a step forward in green chemistry; it’s a potential game-changer for energy portfolios.

The Advantages of Synthetic Graphite Production

An additional benefit of the Hazer Process is its production of synthetic graphite. Traditional methods of obtaining graphite involve mining, which can be environmentally disruptive and resource-intensive. The Hazer Process, however, eliminates the need for mining by synthesizing graphite from methane gas, a waste product readily available in large quantities.

Furthermore, conventional synthetic graphite production typically involves the use of coal tar pitch, a process that generates significant carbon emissions. In contrast, the Hazer Process uses methane, a waste-to-energy conversion that is far more environmentally friendly and aligns with sustainable development goals.

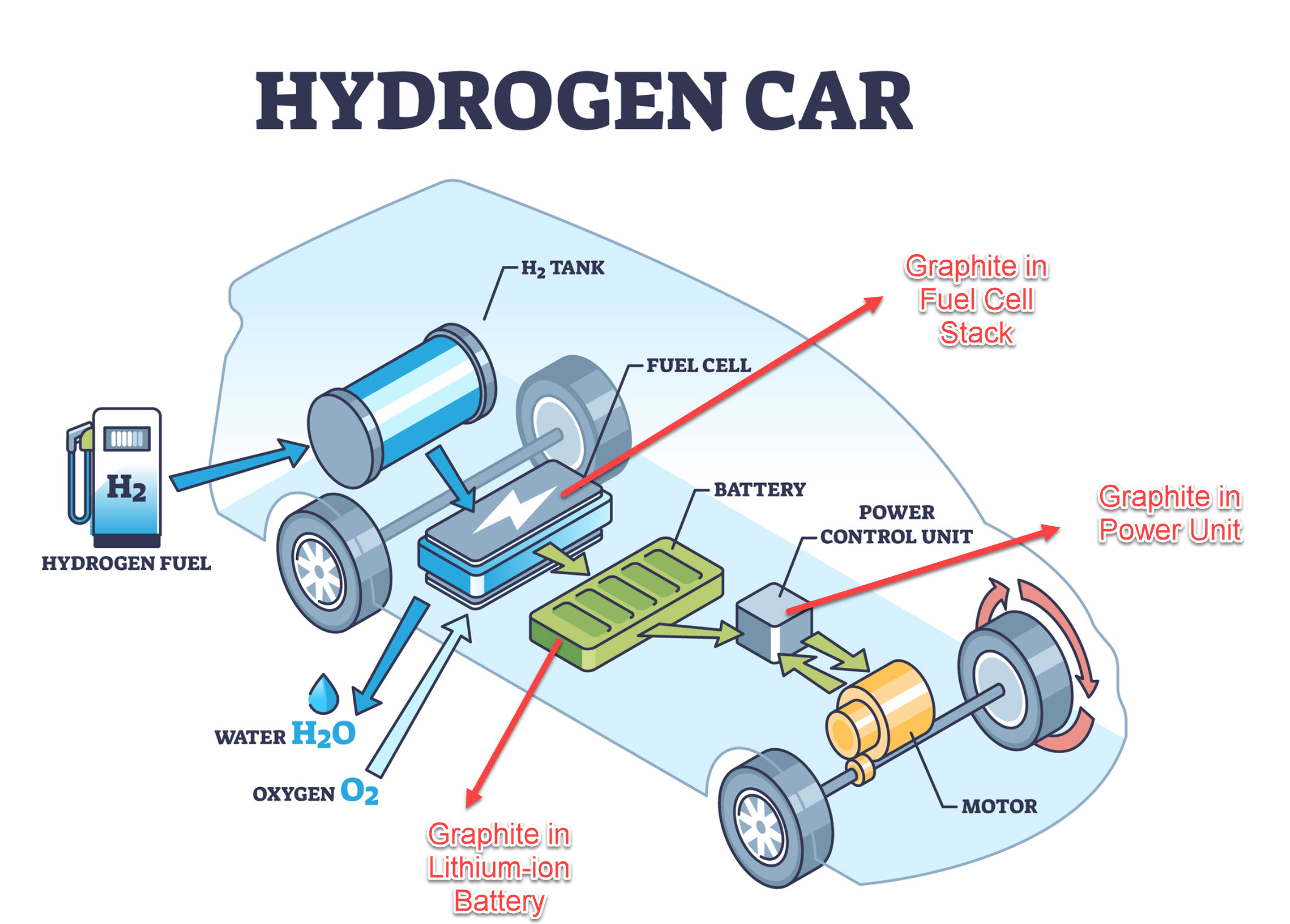

The resulting synthetic graphite is of high quality, suitable for use in lithium-ion batteries, among other applications. This not only meets the increasing demand for such materials in advanced manufacturing and renewable energy storage but also reduces the environmental footprint associated with graphite production.

The Hazer Process effectively targets two thriving markets – the growing demand for sustainable hydrogen fuel and the need for high-purity graphite in lithium-ion batteries and other advanced manufacturing processes. For those closely monitoring industry innovation, Hazer Group exemplifies market disruption through technological sophistication. Their method could potentially lower the cost hurdles associated with clean hydrogen production while also providing a profitable by-product for another rapidly expanding sector.

In conclusion, this Australian company is making significant strides in the renewable energy sectorwith its innovative Hazer Process. Their successful startup of the Commercial Demonstration Plant signals a promising future in low-cost, low-emission hydrogen and high-quality graphite production. The company’s approach not only addresses the growing demand for sustainable energy solutions but also aligns with global sustainability goals.

sectorwith its innovative Hazer Process. Their successful startup of the Commercial Demonstration Plant signals a promising future in low-cost, low-emission hydrogen and high-quality graphite production. The company’s approach not only addresses the growing demand for sustainable energy solutions but also aligns with global sustainability goals.

Their synthetic graphite, suitable for use in lithium-ion batteries and other advanced processes, positions them well in the rapidly expanding clean energy market.

As Hazer Group prepares to ramp up operations in 2024, we eagerly anticipate further advancements from this trailblazing company. Their potential to disrupt the industry and redefine standards in sustainable production could have far-reaching implications for our transition to a low-carbon economy. We look forward to hearing more from this company as it continues to catalyze change in the hydrogen and graphite markets.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.