The Race for Hydrogen Combustion Engines is Officially On

May 31, 2024The Debate Over Hydrogen Combustion in Automobiles

As the automotive industry pushes towards sustainable solutions, the debate over hydrogen combustion engines has intensified. Recently, Volvo ventured into the fray, asserting that hydrogen combustion could meet zero emission standards. This raises numerous questions about the future of automotive technology and its environmental impact.

Understanding Hydrogen Combustion Technology

Hydrogen combustion engines operate similarly to traditional internal combustion engines, but instead of gasoline or diesel, they burn hydrogen. This process theoretically results in water vapor instead of carbon dioxide as a byproduct. However, when compared to their traditional counterparts, hydrogen combustion engines face unique challenges and opportunities.

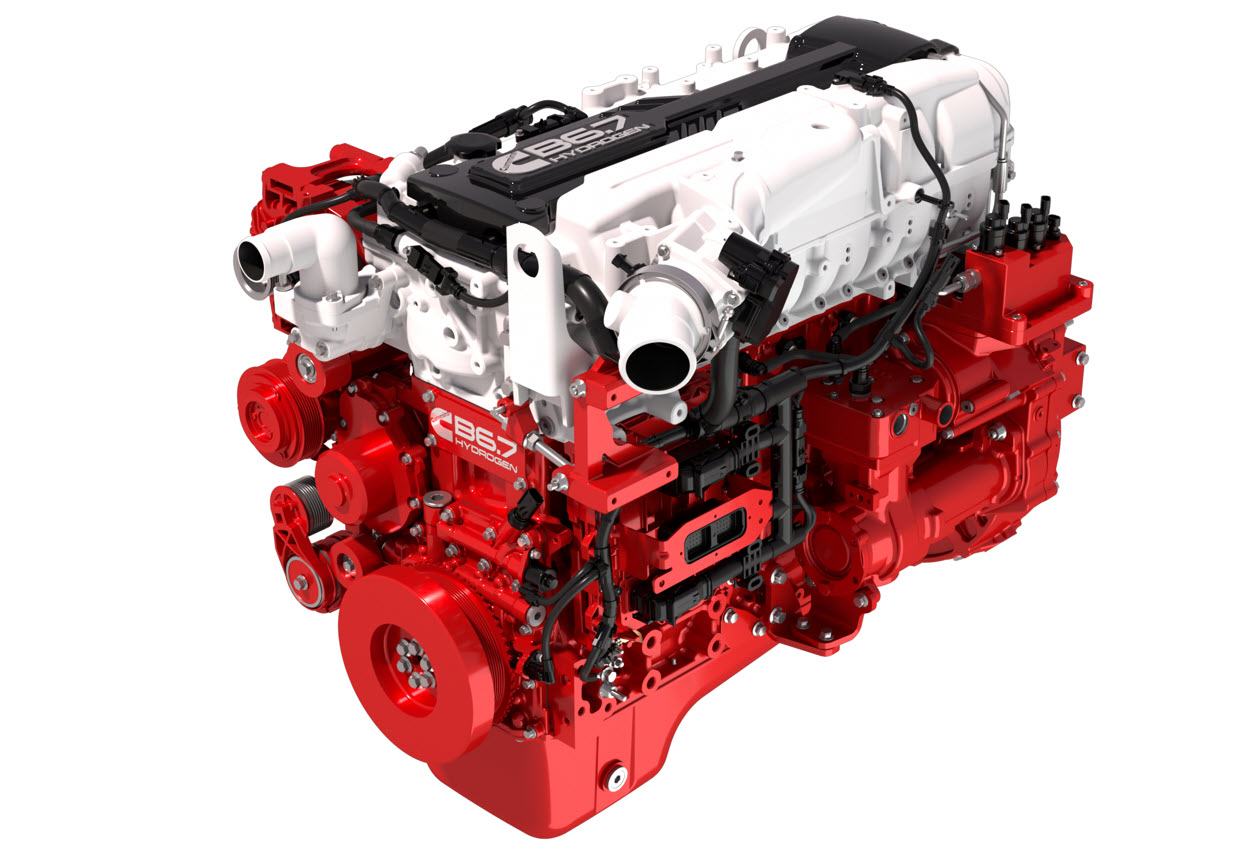

Cummins Hydrogen Combustion Engine – Image Credit Cummins

Currently, hydrogen combustion technology is in an exploratory phase within the automotive industry. Companies like Volvo, Cummins, Hyundai and Toyota believe in its potential, but there still remains a gap between research and widespread commercial application.

Advantages of Hydrogen Combustion Engines

Hydrogen combustion engines present several compelling advantages over hydrogen fuel cells, making them an attractive alternative for zero-emission mobility solutions. These benefits extend across various dimensions such as vehicle design flexibility, cost efficiency, and operational familiarity. Below are the key points that highlight the distinct advantages of hydrogen combustion engines:

- Hydrogen combustion engines are more compact than hydrogen fuel cells.

- Facilitates more flexible and innovative vehicle designs.

- Easier integration into various automotive platforms without major redesigns.

- Maintains or increases interior space and cargo capacity, enhancing vehicle utility.

- Cost considerations favor hydrogen combustion engines.

- Less expensive to manufacture compared to hydrogen fuel cell systems.

- Utilizes established internal combustion engine technologies and infrastructure.

- Allows adaptation of existing production lines and components with minimal modifications.

- Lower production costs can be passed on to consumers, potentially accelerating adoption.

- Operational principles of hydrogen combustion engines resemble traditional gasoline engines.

- Familiarity for mechanics and automotive engineers.

- Minimal retraining required for existing workforce.

- Enhances appeal for auto manufacturers and the wider automotive service industry.

- Facilitates smoother transition to greener technology.

- Maintains robust support ecosystem for vehicle owners.

The Pollution Dilemma

Critics argue that hydrogen combustion isn’t as clean as it seems. While burning hydrogen does eliminate CO2 emissions, it produces nitrogen oxides (NOx), which are harmful pollutants. These emissions pose a significant hurdle in classifying hydrogen combustion engines as truly zero emission.

Existing research presents mixed results, with some studies indicating that NOx emissions can be mitigated through advanced engine designs and exhaust treatment technologies. Nonetheless, the debate continues as the industry seeks conclusive evidence.

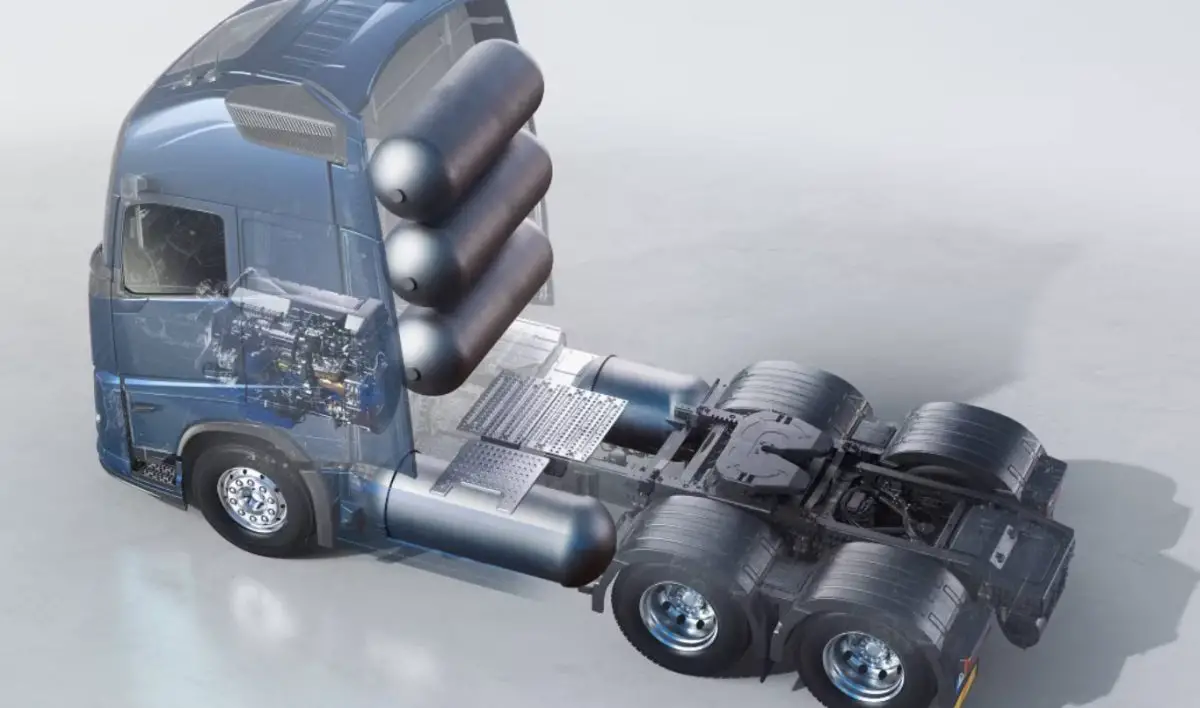

Volvo Hydrogen Combustion Engine Truck – Image Credit Volvo

Volvo’s Zero Emission Claim

Volvo’s stance is bold: they purport that hydrogen combustion can align with the European Union’s stringent zero emission vehicle standards. Their strategy includes utilizing renewable materials and advanced combustion techniques to minimize NOx emissions.

The Swedish automaker plans to leverage green hydrogen, produced using renewable energy sources, to ensure the entire lifecycle of the hydrogen fuel is environmentally friendly. This positions Volvo not just as a car manufacturer, but as a pioneer in sustainable automotive technology.

Regulatory Standards and Compliance

Both UK and US zero emission vehicle standards set a high bar. These regulations require vehicles to produce no tailpipe emissions, a criterion that hydrogen combustion engines must meet to gain classification.

To comply, hydrogen combustion engines must undergo rigorous testing and validation processes. This includes real-world emissions testing and lifecycle assessments to ensure that all aspects of production and operation are sustainable.

The Surge in Hydrogen Combustion Engine Technology

The automotive industry’s interest in hydrogen combustion engine technology is indeed gaining momentum as companies seek alternatives to battery-powered solutions for zero-emission mobility. Recently, Hyundai Doosan Infracore, a unit of HD Hyundai, announced plans to produce hydrogen internal-combustion engines (ICE) for construction and commercial vehicles by 2025. The applications for these engines are seen as a gradual replacement for diesel engines, attracting significant interest from major industry players.

Cummins, for example, is actively testing a hydrogen ICE engine and expanding its investments in hydrogen energy and components. But It’s not just trucks. Toyota is pushing the boundaries by developing hydrogen combustion engines for race cars and even passenger vehicles. The automaker has already rolled out the Mirai, a fuel cell car, but is now exploring a new direction using hydrogen. Toyota is innovating with their hydrogen combustion engine, exemplified by the Corolla Cross H2 Concept.

Take Hyundai Dossan’s hydrogen 11.0L ICE engine, which showcases the capabilities of modern hydrogen technology. It delivers 300 kW (402 HP) of power and 1,254 lb.-ft. (1,700 Nm) of torque at 2,000 rpm, meeting stringent Tier 5/Stage 5/Euro 7 emission regulations. The engine’s emissions are impressively low, falling 90% below current levels to meet Zero CO2 (below 1g/kwh) and Zero Impact Emission standards. These engines are particularly well-suited for road-going semi-trucks and construction equipment, boasting rapid refueling times of just one minute and a range of 310 miles (500 km). When considering maintenance costs, they are also 25%-30% more economical than battery packs or hydrogen fuel cells.

So far, the debate over hydrogen combustion engines as zero emission vehicles is far from settled. Volvo’s ambitious claims and strategic initiatives represent a significant step forward, but they also highlight the challenges ahead. As the industry explores this technology, stakeholders must balance innovation with environmental responsibility.

Ultimately, whether hydrogen combustion becomes a mainstream solution will depend on continued advancements in technology, regulatory support, and market acceptance. What remains clear is that the pursuit of zero-emission vehicles is critical for a sustainable future.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

JCB have already developed hydrogen fuelled Large diggers using their adapted diesel engines successfully. And are now trialiing them world wide in different climates.

Great article.

Would like to find partner in H2 engine development where the design is more like a tandem steam engine with spark combustion … and 2 cycle, not 4. I’ve been researching hybrid steam engines since 1979 (while in engineering at boiler manufacturer). Note that the steam formed when the combustion flash occurs begins immediately condensing, unlike gas or diesel that use the expanding mix to power turbochargers. Direct injection of H2 and O.

The emissions from my vehicle were tested in a Utah state emission facility when it was running on pure hydrogen. The results were very good with just a tiny fraction of what is allowed for NOx. Combustion of H2 in an engine happens much faster than any other fuel so nitrogen doesn’t have time to form an Oxide. They also tested the emissions from burning CNG at the same facility and the exhaust is significantly cleaner than from gasoline. The biggest problem is price and availability of compressed H2. California has around fifty stations, but they are having supply problems and the cost for a gallon equivalent is $35!

My vehicle has a power loss when running on H2, power with CNG, methane, is very good, and power with E85 is better than either. The best fuel I have found is a blend of CNG and H2 that offers the best mileage and power of any other fuel.