Triple Combined Cycle: The last frontier of Electricity Generation

November 29, 2024 0 By Davide SpinosaIn a current global scenario of geopolitical instabilities, retirement of coal assets and increasing interest in environmental responsibility, the various stakeholders of the energy sector are facing unprecedented challenges to meet market needs. The energy producers are looking for alternative technologies able to guarantee higher efficiency and reliability, operational flexibility and long-term profitability in a volatile environment.

SOFC: innovative power source

Within the energy generator field, fuel cells are innovative solutions as the direct electrochemical conversion of the fuel’s energy content into DC electricity removes the exergetic losses associated with the combustion process. In that perspective, Solid Oxide Fuel Cell (SOFC) is very well suited technology for distributed power generation due to its high efficiency and low pollutants emissions in stand-alone configuration. Moreover, SOFC is considered a perfect candidate to be integrated into conventional thermodynamical cycles since:

- Its electrolyte, a non-porous metal oxide (generally yttria-stabilized zirconium oxide), has been proved to be tolerant to carbon monoxide. This allows the anode of the cell to be fed directly with natural gas (NG), which can be converted internally to the SOFC module into hydrogen, through the endothermic reactions of Methane Steam Reforming (MSR) and Water Gas Shift (WGS);

- Due to its high operating temperature (between 650°C-1000°C), a huge amount of the available hydrogen chemical energy is dissipated as heat into the environment. By integrating the SOFC with a thermodynamic cycle capable of converting that wasted heat into useful work, an improvement of the overall efficiency of the process will be achieved.

Triple Combined System

Having said this, a hybrid set-up in which an SOFC is coupled with a Gas Turbine (GT), represents innovative solutions of increasing interest, capable of ensuring very high performance while minimizing environmental emissions. The Hybrid cycle concept can be applied on large centralized power plants with an installed capacity of hundreds of MW.

In that context, Triple Combined System obtained by integrating a SOFC and Gas Turbine Combined cycle (GTCC), is the last frontier of electricity generation in terms of efficiency, with a theoretical overall conversion yield (based on fuel’s Lower Calorific value) 10% higher than those of the latest H series turbogas combined cycle.

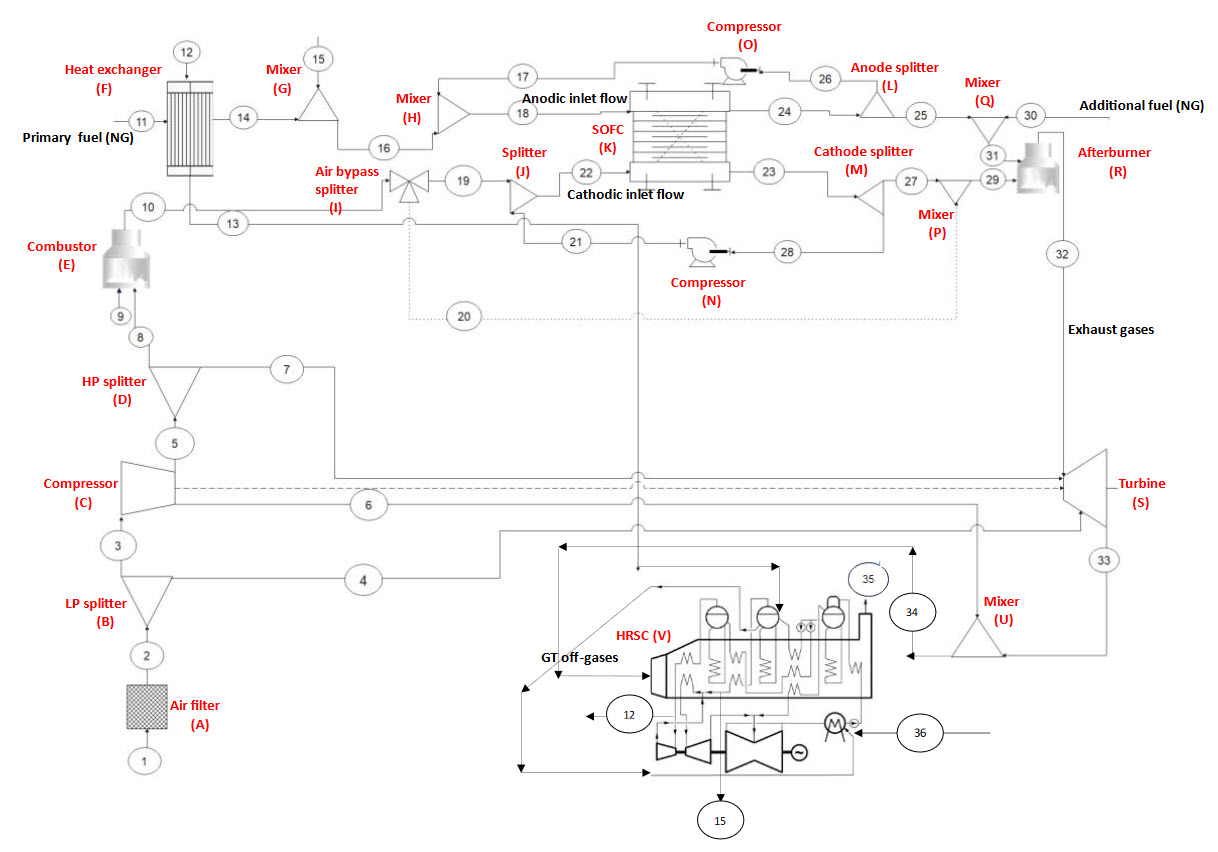

In the configuration of triple combined cycle, the pressurized SOFC is located between the compressor and the expander, both installed along the same shaft and it is connected to the external DC circuit. The primary fuel (natural gas) and oxidant streams are preheated to 650-750°C temperature level required at SOFC inlet before entering respectively the anode and cathode. The anode off-gas, which contains residual fuel species, is mixed with additional natural gas and oxidized by the cathodic outlet depleted flow in the afterburner. The exhaust gases are expanded in the turbine which drives an electrical generator where the net shaft power is converted into electrical one. At the outlet of the expander, the thermal energy of the GT off-gases is recovered into a 3-pressure levels Heat Recovery Steam Cycle (HRSC).

The system under investigation can reach an outstanding overall efficiency of around 80%, achievable when the primary natural gas flow is maximized and for pressure ratio relatively low (in the range of 13- 16). Considering a plant’s theoretical installed capacity of close to 800 MW, the SOFC produces around 60% of total electrical power delivered, GT 30% and the HRSC 10%.

However, due to structural problems, flow distributions and temperature control within the cell, it is impossible to set-up SOFC modules of tens or hundreds of MW. It might be conceivable to distribute the power output from the fuel cell over a series of modules in parallel, each of maximum size of kW or a few MW. In any case, due to the high cost of the technology and the decay of performance over time that has yet to be verified, the triple combined configuration for large-scale power generation has not found commercial or industrial interest nowadays.

In the future years, with the development of a scale economy on fuel cell, an increasing request to maximize electricity production yields and to respect strict environmental limits on emissions, this technology will certainly find rising investments and practical application.

About The Author

Certification - Galileo Master Certificate (GMC) in Renewable Energy Solutions, Biomass, Hydrogen Energy, Heat Pumps, Electric Vehicles, Combined Heat and Power United Nations University Institute for the Advanced Study of Sustainability: Net Zero 101 Author Bio I am currently working as a Gas Turbine Commissioning Engineer for Siemens Energy. Being able to work worldwide in power generation plants allowed me to combine two of my passions, the energy and traveling. I believe the ongoing energy transition process must be seen as a collective stimulus, both scientific and social, to find innovative technological solutions where everyone is called to put as much effort as possible to ensure a sustainable future. This is why I have been personally trying to deepen the renewable energies field, focusing in more detail on the potential of hydrogen as an alternative fuel. When I am not out traveling, I try to spend time with the people closest to me and reading about geopolitics.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.