H2-Industries to produce clean hydrogen while cleaning ocean plastic waste

May 25, 2022An innovative ship design will be used for collecting the plastics and convert it into usable H2.

H2-Industries has teamed up with naval architecture company TECHNOLOG Services for the development of 3D ship designs that would collect ocean plastic waste to make clean hydrogen.

The collected plastics will be used for producing H2 that will power the ship and other applications.

The designs the companies will create are intended to result in a ship that will be able to collect plastic waste out of the ocean. Marine plastic waste is a considerable environmental and health problem that is rapidly worsening worldwide. The ship will collect the plastics and convert them into clean hydrogen for powering the ship itself. The surplus H2 produced by the ship will be stored and brought back to the shore for use in other applications.

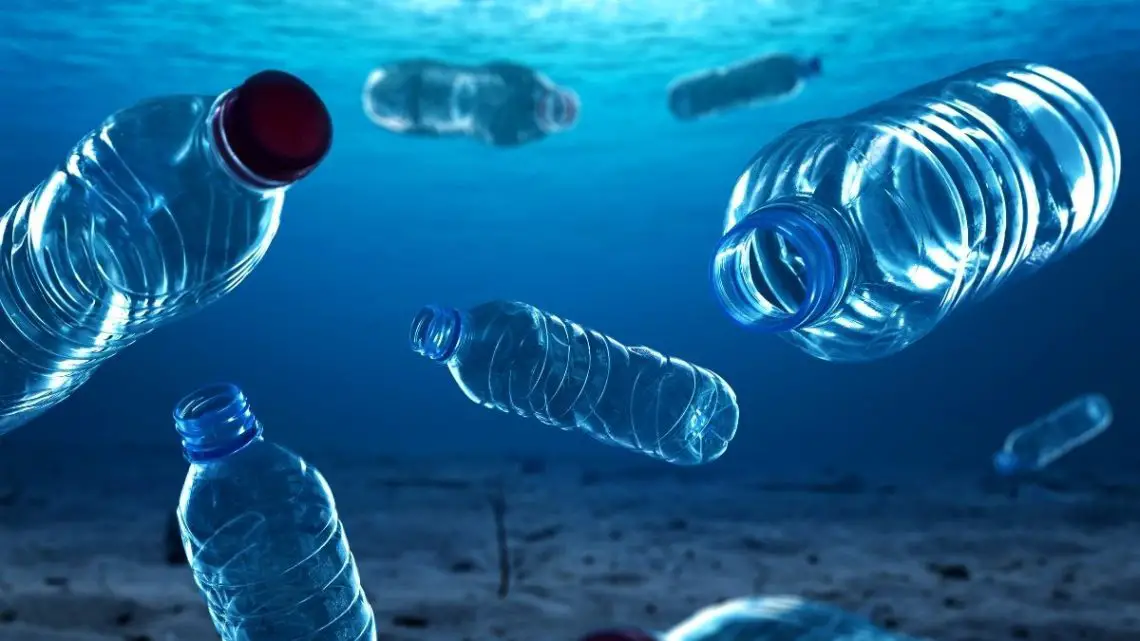

Ocean plastic pollution is expected to have more than doubled by 2030, according to data from a UN Environment Programme (UNEP) assessment. Waste plastics are the largest form of ocean litter, comprising up to 80 percent of all marine debris found in both surface waters and in deep-sea sediments.

International Union for Conservation of Nature (IUCN) data showed that at least 14 million tons of plastic waste is added to oceans worldwide. Every continent experiences plastic waste washing up on their shorelines. Densely populated areas and popular tourist destinations are particularly affected by high levels of washed-up plastics.

The 150-meter-long ship will work with two smaller vessels for plastic collection and clean hydrogen production.

The size will be finalized depending on optimal storage capacity for the H2 it produces. The intention is to have the ship travel at four knots with plastic that two smaller vessels have collected while towing a two-mile net that collects plastic waste from the surface down as far as ten meters (33 feet).

The ship’s open bow design will make it possible for collected plastic waste to be sent onto conveyers that will transport it into the ship’s storage hold.

From the hold, the plastic waste will undergo a thermolysis process used by H2-Industries plants on shore. That will convert it into a clean hydrogen. The company expects to be able to produce 100 kilograms of H2 for every 600 kilograms of plastic waste it collects.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

“We think it’s just not going to happen without hydrogen. It will be really helpful for transport, for storage, and for other different applications.”

Exactly, Karsten Wilbrand.

So why are we making it a two-step solution (battery, then hydrogen) when we could go directly to hydrogen and get there faster. If time is of the essence in climate change, why are we spending the limited time and resources that we have on fast chargers — all of which will become obsolete when hydrogen takes off exponentially.