Expediting Mass-Market Accessibility to Water Electrolyzer Technology

March 10, 2022For centuries, the adage “slow and steady wins the race” has withstood the test of time —rooted in an age where the notions of electrical power, energy efficiency, carbon footprints, and a climate crisis were nonexistent. However, in the 21st century, we are all too familiar with these concepts; the game has changed. The race is on to save the planet, and slow and steady will no longer be the winning strategy. Events are taking their toll here and now.

Stopping the climate crisis from escalating and starting to reverse the impact requires expediting solutions that stand to make a significant contribution to a net-zero-carbon, fully sustainable world. In fact, the U.S. Department of Energy (DOE) recently launched a hydrogen Energy Earthshots Initiative aimed at boosting reliable clean energy development and affordability. Integral to this vision will be not only accelerating research and development but also making solutions widely available at a cost that makes them accessible to, attractive for, and utilized by the masses.

One major focus is the production of green hydrogen energy through expediting water electrolyzer technology development and manufacturing.

There is a promising collaboration underway—and leading the way—that has brought together the National Renewable Energy Laboratory (NREL), Los Alamos National Laboratory (LANL), and The Chemours Company Advanced Performance Materials (APM), along with other contributors bringing unique capabilities to the table, including Lawrence Berkley National Laboratory, Sandia National Laboratories, Idaho National Laboratory, and Lawrence Livermore National Laboratory. The project, Performance and Durability Investigation of Thin, Low Crossover Proton Exchange Membranes for Water Electrolyzers (PEMWE), stems from the HydroGEN consortium, part of the DOE’s Energy Materials Network, and is funded by the DOE’s Hydrogen and Fuel Cell Technologies Office. Working toward a commercial PEMWE-specific membrane, the project is pursuing ambitious goals to increase energy supply as well as reduce energy costs and environmental impact by addressing a critical gap in PEMWE technology, and to fast-track solutions that meet present and future needs.

PEMWE initiatives are driven by the need to strike an optimum balance of electrical efficiency and load-following capability, membrane strength and permeability, safe operation, and ensuring the flexibility that makes it all viable and advantageous for diverse applications. Each core partner leverages a unique strength that contributes to the larger whole. NREL possesses highly advanced PEMWE testing capabilities and diagnostics, LANL is a leader in the determination and study of PEM durability, and Chemours brings the manufacturing of Nafion™ Perfluorosulfonic acid polymers and the largest supply chain of water electrolyzer membranes today. With the other DOE labs, the project represents a culmination of science, technology, data, and manufacturing expertise.

The Chemours Company, with the Advanced Performance Materials business, has been making Nafion™ membranes for decades, evolving science and production as new resources and discoveries arise to drive bigger and better opportunities for the hydrogen economy. What makes this so exciting is that now, for the first time, we have highly specialized testing available in the PEMWE space, plus extensive, highly relevant experience from other collaborators. It’s the combination of all these specializations and depth of resources that will allow us to truly fast-track solutions and establish foundations that will make their use feasible beyond the labs—and beyond just a few elite populations that can access and afford them. This is how we will make a significant impact on the health of the environment and quality of life on a global level.

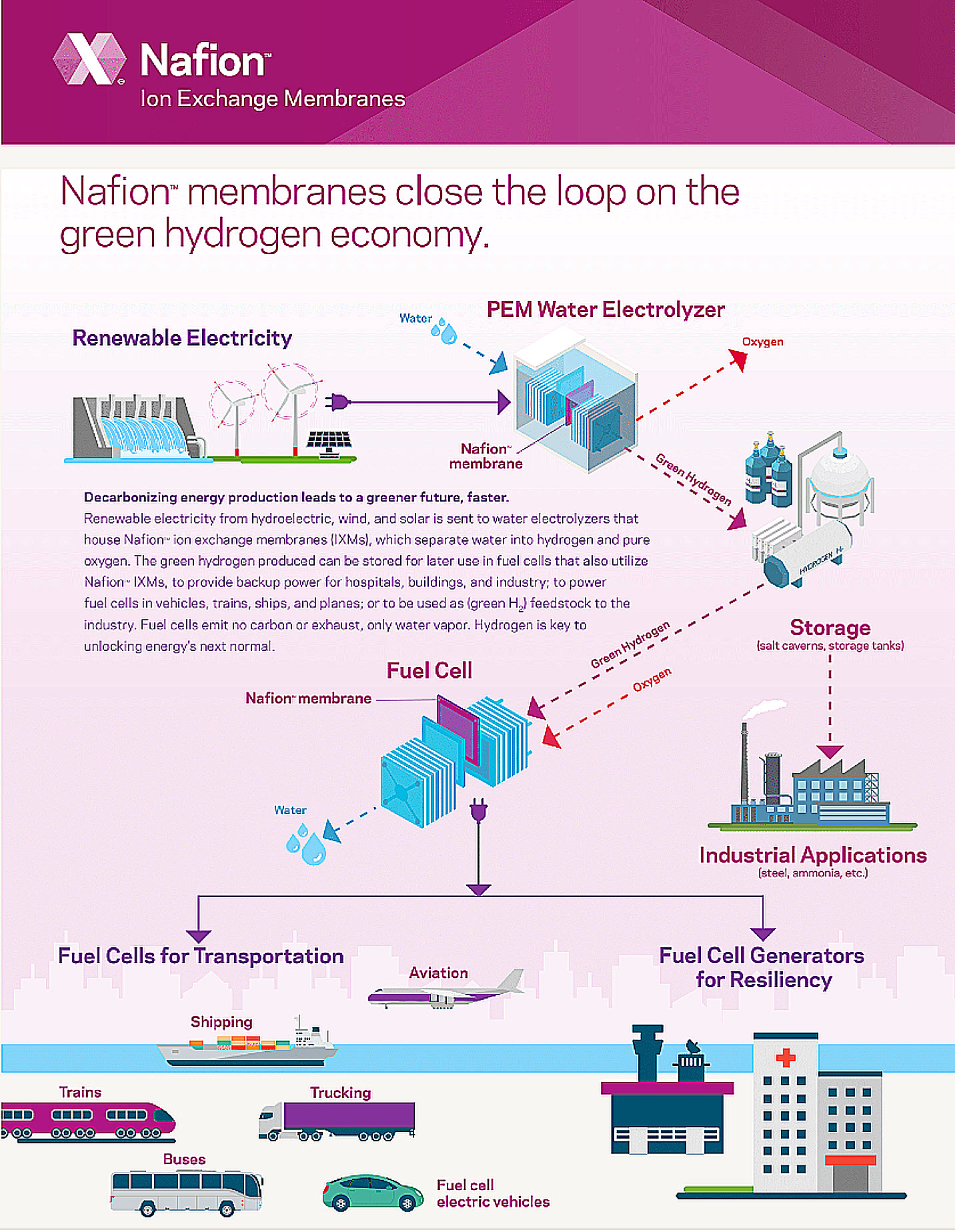

While this project is largely focused on membrane technology for the production of green hydrogen energy, it is not progressing in a vacuum.

The teams involved keep a steady vision on how this hydrogen energy will be used, especially in fuel cells, which can power everything from mobilization—trucks, trains, and other transport—to combustion processes, production of green chemicals, fuel refining, and more. In addition, what’s being learned and applied to improve electrolyzer membranes will very likely be leveraged to benefit fuel cell membranes and other devices in the future.

This project respects the individuality of, as well as the synergy between, a number of partners, all coming together to help solve a world issue. These membranes are only as powerful as the technologies being developed to put them to use, and the partners in our group—as well as many other initiatives—are working toward the same goals of achieving greener energy that is more affordable and ubiquitous in society. It is only when all these efforts converge and we gain the ability to evolve through each other’s influences that we can confidently arrive at solutions that will enable our ultimate goals to be realized.

A final point in “the race” to bring low-cost, high-impact water electrolyzer technology to mass markets is that additional challenges remain. Achieving ultimate goals will take time and investment to, for example, create an infrastructure for delivery of clean hydrogen. It will require a change in thinking and acting, starting with risk-takers and progressing through levels of adoption. It will require patience to implement a strategy that distributes technologies, and it will require the realization that the race will never be over. Markets, society, and ways of life are constantly changing. So science, technology, and manufacturing, as well as investors from public and private sectors, must be prepared to support where we are and where we are headed. By maintaining the readiness and ability to implement solutions today that become the foundations of solutions for tomorrow, we can continue the path toward clean energy, net-zero emissions, and a sustainable planet.

How it all works…

Dr. Andrew Park is a Principal Engineer with The Chemours Company and has over a decade of experience in the manufacture and evaluation of membranes and membrane electrode assemblies for hydrogen fuel cells and water electrolyzers. Currently, Andrew leads efforts in Nafion™ membrane research and development at Chemours and is the principal or co-principal investigator on three Department of Energy programs aimed at next-generation materials in hydrogen applications. Andrew is passionate about enabling the hydrogen economy through transformational materials research and commercialization of promising technologies.

Dr. Andrew Park is a Principal Engineer with The Chemours Company and has over a decade of experience in the manufacture and evaluation of membranes and membrane electrode assemblies for hydrogen fuel cells and water electrolyzers. Currently, Andrew leads efforts in Nafion™ membrane research and development at Chemours and is the principal or co-principal investigator on three Department of Energy programs aimed at next-generation materials in hydrogen applications. Andrew is passionate about enabling the hydrogen economy through transformational materials research and commercialization of promising technologies.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

Renewable Natural Gas is a non-fossil fuel requiring no drilling or fracking. It is actually “carbon negative” due to the capture of biogas from organic waste and converting it to pipeline quality Renewable Natural Gas. This biogas would otherwise be released to the atmosphere as GHG. There is an endless and infinite supply of organic waste to produce RNG. This RNG can be converted to hydrogen with steam methanation “on site” with HyGEAR units. No new infrastructure necessary to transport the hydrogen as the RNG can be transported in existing natural gas pipelines to the onsite HyGEAR unit. Produce all the Renewable Electricity possible and use it to replace electricity presently produced by coal burning power plants. Don’t waste it on electrolysis of water to produce hydrogen that then has to be transported hundreds of miles to the enduser. We’re running out of time. This technology is present today.

“New Research Suggests Renewable Natural Gas Can’t Deliver The Carbon Neutral Future We Need”

forbes.com/sites/brentanalexander/2020/05/28/new-research-suggests-renewable-natural-gas-cant-deliver-the-carbon-neutral-future-we-need/