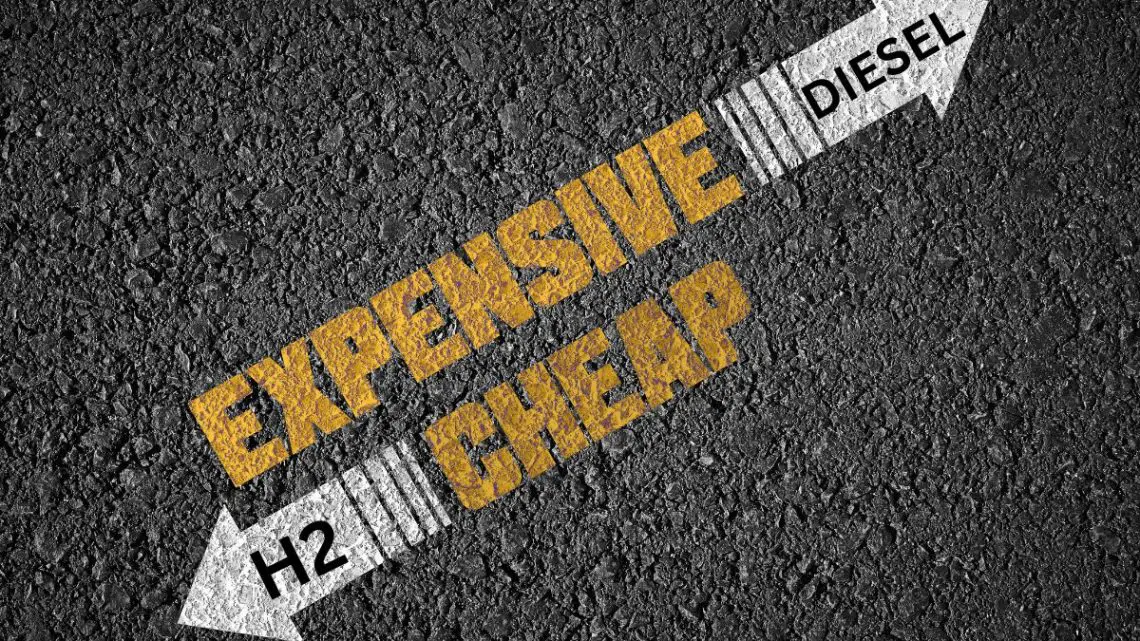

Ryze Hydrogen says hydrogen combustion engines cheaper than diesel

September 27, 2022The company points to trucks using H2 ICEs as the more economical choice.

As companies seek to decarbonize their truck fleets, Ryze Hydrogen says that hydrogen combustion engines are the way to go for a more economical choice.

While cleaner for the environment than diesel, the company also says they make financial sense.

The UK green energy supplier’s claim arrives at a time in which truck manufacturers are seeking to offer fleet managers affordable, economical ways to achieve decarbonization. Though most companies are currently looking at fuel cells in order to be able to use H2 as a clean fuel, there is a growing movement toward the use of hydrogen combustion engines.

Cummins has already unveiled a medium-duty concept truck using an H2-fueled internal combustion engine (ICE), which drew substantial attention in Germany at the IAA Transportation exhibition. Similarly, Westport Fuel Systems also unveiled its own HPDI hydrogen ICE engine for heavy duty vehicles earlier this month.

There are a number of benefits that hydrogen combustion engines have to offer over fuel cells.

To start, the technology used by ICE is already familiar to engineers and mechanics worldwide who provide maintenance and repairs to trucks and other medium- and heavy-duty forms of vehicle, equipment and machinery. The technology could be incorporated into a spectrum of types of vehicles and machinery, not just trucks.

Cummins demonstrated the ease of H2 ICE deployment by exchanging a Mercedes-Benz Atego 4×2 truck’s diesel engine for a 6.7-liter H2 ICE engine. Performance, cargo capacity and payload were all fully preserved.

Westport has gone so far as to say that its own H2 ICE engine offers a notable increase in performance when compared to its diesel equivalent, including 20 percent more power and 18 percent improved torque.

By using diesel engine architecture and engine manufacturing infrastructure already in place, Westport has said that its engine offers the lowest-cost opportunity for achieving CO2 reduction target compliance. This could also help to minimize a company’s transition cost while decarbonizing.

“We like to think of it as a game changer without the change,” said Westport Fuel Systems CEO David Johnson when referring to hydrogen combustion engines.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

As the hydrogen engines produce more torque and hp for the same capacity it would be good to understand why this is and as they are cheaper to produce it woud be good to understand why, is the compression rate lower? Does this mean that diesel engines in cars will soon be replace with a simpler engine? If they are that beneficial why has it taken so long to make it happen?

The 26,000 freight diesel locomotives in the US create a scale economics incentive to produce lighter, cheaper piston swap-ins for mid-life overhauls.

The earliest bottle neck may be human engineering and craft skills.

As Federal and state governments use funds to incent post-carbon infrastructure, some of the earliest resources should flow to universities and community colleges. Present diesel employees might be trained free to minimize disruption and transition time.

What is the plan for dealing with the NOx side of H2 ICEs? It never seems to get a mention in these articles yet it is a powerful greenhouse gas that fuel cells do not produce.

Although this article talks about the benefits from hydrogen (H2) powered internal combustion (IC) engines over fuel cells, it does not mention the downsides of them which is that IC engines also produce large amounts of nitrogen oxides (NOx) which are harmful to our health and the environment, whereas fuel cells do not do this, as the nitrogen in the air (around 80%) is kept away from the oxygen that is used to release the energy of hydrogen, by a membrane that is only permeable to hydrogen ions (H+) and not nitrogen. Also, IC engines are not as efficient in converting the H2 energy into traction (around 30%) compared with a fuel cell and electric motor (around 60% x 85% = 50%). That said, using H2 in a converted IC engine is a useful way to reach 2050 by refitting a vehicle without scrapping it before then.

Nice to see that a company has come up with a sensible plan to make larger vehicles cleaner and more greener now rather then having to wait another 20 years for someone to develop a vehicle that would be able to carry the same weight the same distance as they can now.