New 3D technology could benefit industrial hydrogen production

September 10, 2018Researchers invent 3D self-assembled steam electrode that can be scalable for hydrogen production.

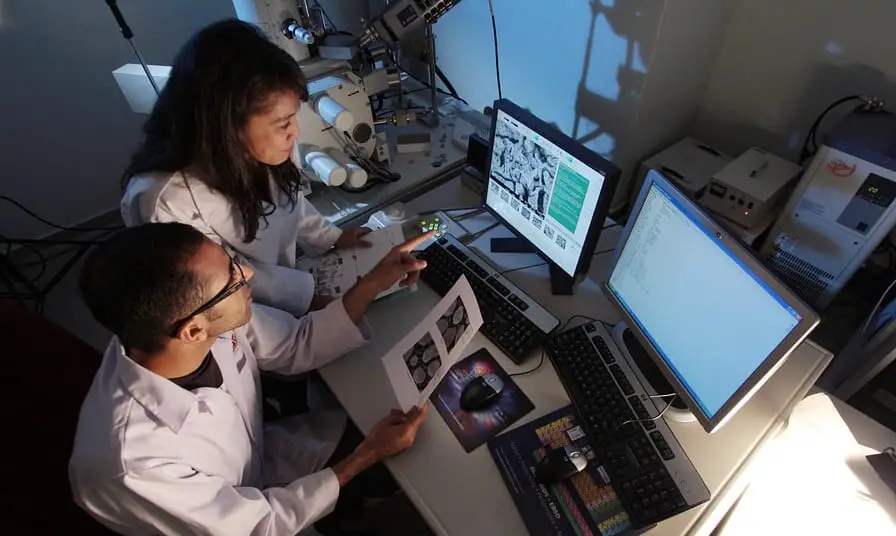

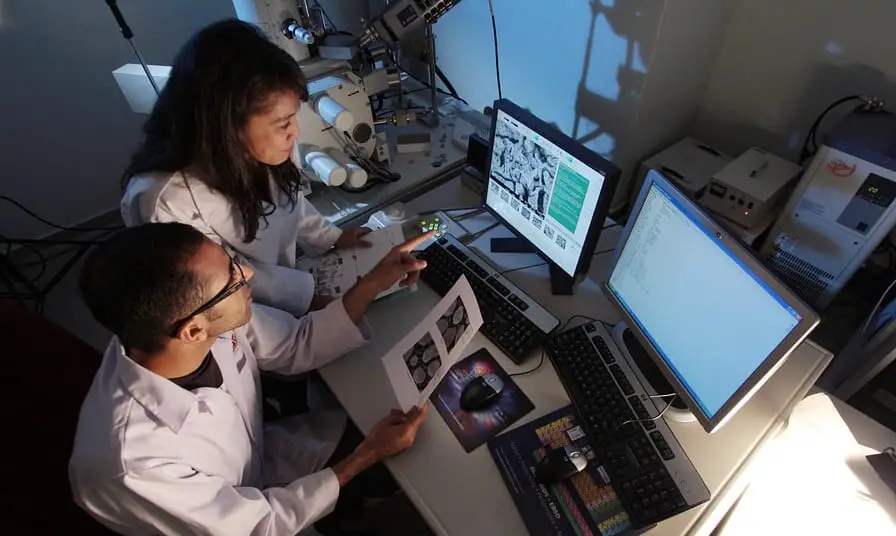

Idaho National Laboratory researchers are one step closer to being able to produce industrial hydrogen with greater efficiency. This has been made possible due to their invention of a 3D self-assembled steam electrode.

The researchers demonstrated high-performance electrochemical production at low temperatures.

In the paper published by the journal Advanced Science, the researchers revealed advances in the production of industrial hydrogen. This is used in petrochemical manufacturing and oil refining, as well as an environmentally-friendly green fuel for vehicles.

Using their 3D self-assembled steam electrode, the researchers demonstrated high-performance electrochemical hydrogen production at a lower temperature compared to what had previously been possible. This was achieved because of a ceramic steam electrode that self-assembles from a woven mat.

“We invented a 3-D self-assembled steam electrode which can be scalable,” said one of the researchers, Dr. Dong Ding, reported Phys.org. “The ultrahigh porosity and the 3-D structure can make the mass/charge transfer much better, so the performance was better.”

The researchers’ technology could result in cleaner industrial hydrogen production.

Although hydrogen is a green alternative fuel, due to it releasing only water when it burns, the current production methods are far from clean. The reason is hydrogen is typically obtained from steam reforming hydrocarbons, for instance, natural gas. This process requires fossil fuels, which results in carbon byproducts. Due to this fact, most hydrogen fuel produced today isn’t ideal for sustainable production.

The researchers’ 3D self-assembled steam electrode, which is the product of a highly efficient proton-conducting solid oxide electrolysis cells (P-SOECs) of their design, requires only water and electricity to split water molecules to generate hydrogen and oxygen. The electricity can come from any source, including renewable forms of energy like solar and wind, which can mean low-emission or even emission-free production.

However, what truly makes the researcher’s technology unique is that their P-SOECs operated below 600º C. This means that they managed to produce hydrogen at an on-going high-sustained rate for days throughout the testing period. This is reportedly cooler by hundreds of degrees compared to conventional high-temperate steam electrolysis methods.

This is important because being able to conduct electrolysis efficiently at as low a temperature as possible offers many benefits, among which include reducing the energy requirement for production, lowering production cost, and  making the hydrogen production process more durable.

making the hydrogen production process more durable.

The discovery made by Dr. Dong Ding and his colleagues could offer a more efficient approach for high-volume industrial hydrogen production.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.